For over half a century, the HUESKER Group has been a pioneer in transforming the way we think about road repair. With their extensive range of HaTelit asphalt reinforcement products, HUESKER has led the way in sustainable roadway rehabilitation, effectively addressing the widespread issue of asphalt reflective cracking. A notable example is the application of HaTelit polymeric asphalt reinforcement during the rehabilitation of Texas State Highway (SH) 21, which has proven successful in minimizing reflective cracking and potentially reducing the required thickness of asphalt overlays.

Addressing Asphalt Reflective Cracking

Reflective cracking is a significant challenge for roads worldwide, particularly in regions like Central Texas where roadways are built on expansive subgrade soils with high swell-shrink characteristics. This leads to the formation of cracks and ruts, significantly deteriorating ride quality and road-user serviceability. Given Texas State Highway (SH) 21 foundation on such challenging terrain, it was an ideal candidate for HUESKER's innovative solution.

Additional Benefit: Increased roadway structural capacity

Integrating HaTelit polymeric asphalt reinforcement allows for more even load distribution across the road surface while maintaining adequate bonding between pre-existing and new asphalt layers. This not only minimizes reflective cracking but also reduces surface deformation and tensile strains under repeated traffic loading. As a result, the structural capacity and durability of the road are enhanced, extending its service life.

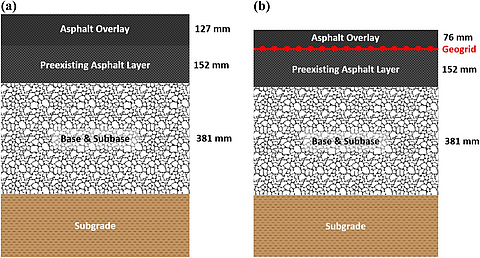

To further minimise the environmental impact, pavement engineers from the Texas Department of Transportation collaborated with researchers from the University of Texas at Austin and HUESKER to reduce the thickness of the asphalt overlay without compromising pavement performance. The rehabilitation of SH21 stands out as one of the few projects in Texas - and indeed the US - to use HUESKER's HaTelit polymeric asphalt reinforcement product to mitigate reflective cracking while reducing the design thickness of the HMA overlay.

Reduced construction and annual maintenance cost

This approach not only addresses the immediate cracking issues but also offers broader benefits by increasing the road's structural capacity. By effectively managing stress within the asphalt layers, it reduces the need for thick overlays, thereby decreasing both construction and maintenance costs. This innovative method has been recognized for significantly alleviating the financial burden associated with road repairs.

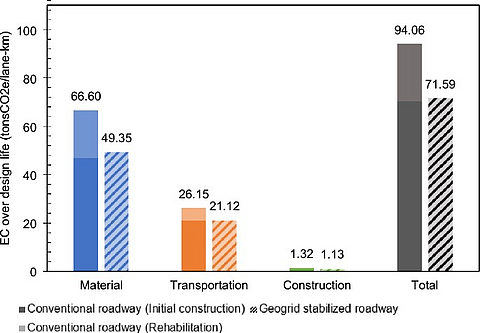

Sustainable Solution: 30% reduced Carbon Footprint!

Beyond the economic advantages, HUESKER's strategy stands out for its environmental benefits. The use of HaTelit polymeric asphalt reinforcement has been shown to reduce the carbon footprint associated with road rehabilitation by approximately 30% compared to conventional asphalt overlays. This reduction is achieved through decreased reliance on raw materials and lower emissions from their extraction, transportation, and use.

In summary, HUESKER's work on SH21 is a testament to their vision of a more sustainable future for roadway rehabilitation. By merging technological innovation with a commitment to environmental stewardship, they have provided a model for road repair that promises not only longer-lasting roads but also a healthier planet. This story is a beacon of hope, demonstrating that with the right approach, we can build infrastructure that serves our needs today without compromising the well-being of future generations.

Yours, Vinay