Lubratec® Tube Cool

The Lubratec Tube Cool is a ventilation system including a cooling function, which is particularly effective in barn ventilation due to its high efficiency. Tube ventilation systems are often used in large barns such as in dairy farming, but also in pig or poultry farming. Our tubes provide your animals with an ideal barn climate and thus prevent dangerous heat stress.

Using a 3D stable climate simulation, the cooling tubes are individually calculated and subsequently produced. The tubes can be expanded at any time with modern control technology, which makes automatic climate control and year-round use possible. You are welcome to make use of our on-site veterinary consultation to achieve maximum animal welfare!

Lubratec Tube Cool

Product benefits

|

Impact of Tubes

On livestock farming

Product benefits

- Constant food intake and longer lying times

- Shown to be most cost-effective system on market*

- bessere Fruchtbarkeit

- Up to 3 ltr increase in milk yield per cow**

- Measurable stress reduction – healthier cows

Impact on calf farming

37 calf barns were fitted with Lubratec Tubes Air. 66-68 %** fewer respiratory illnesses were observed as a result, leading to a 72-87 %** reduction in the costs for antibiotic treatment.

* Basis of comparison: Cooling systems with wind chill effect; defined air speed per animal; purchase costs and energy costs for a two year period (for a constant fan running time in hours).

** Compared to dairy cows kept in unventilated barns and under ideal conditions.

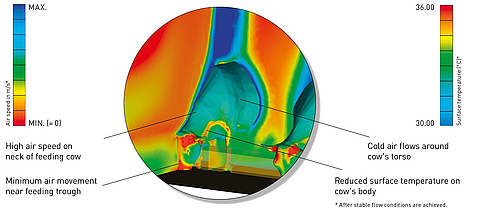

Air Flow Simulation

Efficient cooling with optimum air speeds

Air speed on animal's back

> 1.5 m/s for cubicles

> 2.5 m/s for feeding stations

Options for regulating yield

All tube systems can be combined with state-of-the-art control technology to allow year round use.

Upgrade to EC fans

| Manual controller, continuous (230 V)

|

Temperature-driven controller (230 V)

| Agricultural computer (0–10 V)

|

Simple temperature-driven

|

Further information