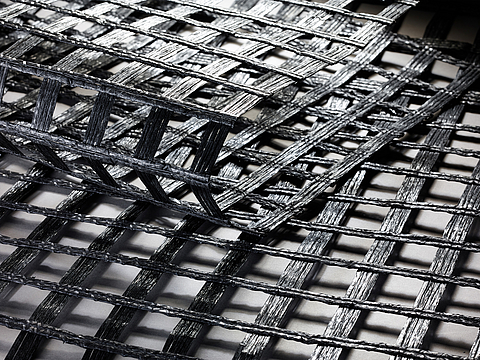

Basetrac® Grid for Base Reinforcement

High-strength geogrid for road base and sub-base reinforcement

Basetrac Grid is the standard product for base reinforcement applications available in two raw materials: polypropylene or polyester. The alkali resistance of the polypropylene material allows its use even in cement-stabilized soils. In addition to the conventional version, the polyester geogrids are also available in ecoLine. In this sustainable product line, the yarn is made from recycled PET bottles and has identical product properties to virgin PET yarn. The flexible material of the geogrids exhibits no memory effect (i.e. it shows no tendency to roll up after laying), allowing much faster and easier installation than with similar products. The high interaction flexibility allows good interaction between soil and reinforcement grid.

Cost savings can be achieved through project-specific selection of the required strength (20-80kN/m). The high-tensile geogrid, which is polymer-coated to protect against UV radiation and installation damage, provides reliable long-term reinforcement for base courses. The production of higher tensile strength and geogrids made of polyvinylalcohol for special applications is possible by request.

Basetrac Grid has been shown to reduce the quantity of base material needed, in comparison to unreinforced constructions. All this makes Basetrac Grid a safe and durable solution for base reinforcement.

Features

Polypropylene or Polyester as raw material

High tensile strength in conjunction with low strain

Flexible and dimensionally stable geogrid

High interaction flexibility

No ""memory effect""

Good UV resistance due to polymer coating

High robustness and straightforward installation

Polypropylene suitable for alkaline environments, e.g. in conjunction with cement stabilisation or recycled rubble

Basetrac is a registered trademark of HUESKER Synthetic GmbH.

Up until February 2017, Basetrac Grid products were known as Fornit.

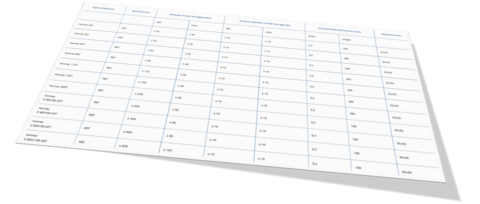

Technical data

| Type of Material | Raw Material | Ultimate Tensile Strength kN/m | Strain at Nominal Tensile Strength (%) | Standard Roll Dimensions (m/m) | Meshsize (mm) | |||

|---|---|---|---|---|---|---|---|---|

| MD | CMD | MD | CMD | Width | Length | |||

| Grid PET 30 | PET | ≥ 30 | ≥ 30 | ≤ 10 | ≤ 10 | 5,00 | 200 | 25 x 25 |

| Grid PET 40 | PET | ≥ 40 | ≥ 40 | ≤ 10 | ≤ 10 | 5,00 | 200 | 25 x 25 |

| Grid PET 65 | PET | ≥ 65 | ≥ 65 | ≤ 10 | ≤ 10 | 5,00 | 200 | 25 x 25 |

| Grid PET 80 | PET | ≥ 80 | ≥ 80 | ≤ 10 | ≤ 10 | 5,00 | 200 | 25 x 25 |

| Type of Material | Raw Material | Ultimate Tensile Strength kN/m | Strain at Nominal Tensile Strength (%) | Standard Roll Dimensions (m/m) | Meshsize (mm) | |||

|---|---|---|---|---|---|---|---|---|

| MD | CMD | MD | CMD | Width | Length | |||

| Grid PP 30 | PP | ≥ 30 | ≥ 30 | ≤ 7 | ≤ 7 | 5,00 | 200 | 25 x 25 |