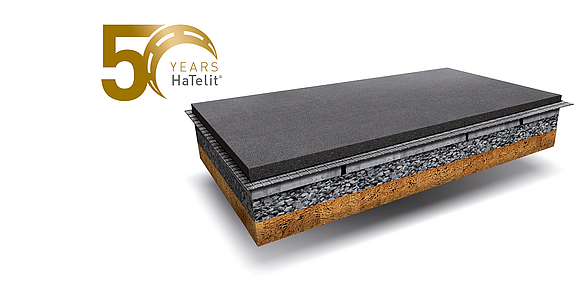

Asphalt reinforcement for the efficient and

sustainable rehabilitation of traffic surfaces

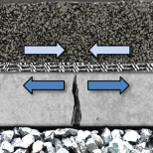

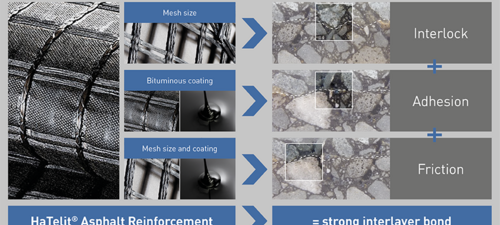

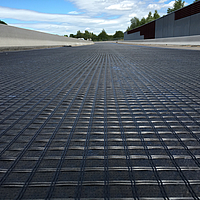

Asphalt reinforcements (asphalt reinforcements, asphalt inlays) are today an integral part of road rehabilitation in road construction. Due to continuously increasing mobility, our roads are also becoming more and more stressed. In many places, roads are ageing and it is urgently necessary to clear the rehabilitation backlog and to repair the old, dilapidated asphalt roads and to delay the undesirable reflection cracking, which is the cause of many road damages, in the long term. Other reasons for reflection cracking are the natural temperature fluctuations and the different temperature behaviour of asphalt and concrete. With conventional asphalt road construction, high stress concentrations at the crack tip result in crack propagation that penetrates into the top asphalt surface layer. Our solution: asphalt inlays made of particularly flexible geogrids, which we manufacture from various high-quality raw materials in order to be able to respond to individual requirements. For easy installation, they are already provided with a unique, bitumen-based coating (bitumen content > 65 %) at the factory. Compared to conventional construction methods, road rehabilitation with asphalt reinforcement benefits from shorter installation times, less material input and saves not only costs, but also harmful CO2 emissions thanks to the more sustainable service life due to 4-fold delayed cracking.

Mike Samueloff

Your contact person

As Business Development Manager for the HUESKER’S North American HaTelit paving interlayer business, Michael (Mike) Samueloff leads HUESKER in the execution of market strategies, product development and sales strategies, partnering with their independent dealer network that has successfully marketed, sold and supported the HaTelit paving line throughout North America. He also holds invention and patent records for the development of two paving interlayers currently sold in the commercial marketplace today and is also past President of the Asphalt Interlayer Association (2016-2017). Currently he chairs the Interlayer Task Group for the Geosynthetic Materials Association and is a member of the Interlayer Sub-Committee of the Transportation Research Board-National Academy of Sciences.