Cogatec® Weatherproof Silo Covers

Tank cover for the reduction of emissions

The Cogatec Weatherproof Silo Covers with central column and the self supporting Silo Cover were developed to reduce emissions generated in the tank and to reduce water entry into the tank. The roof construction for slurry tanks made of concrete or steel reduces emissions of gas and ammonia by more than 95 % and thus fulfils the high requirements for immission protection.

The weather protection roof as well as the strap system are supported by a stainless steel central support. The external bracing is carried out by means of stainless steel ratchets and high-strength tension belts. The round tube inserted into a hollow seam is braced against the outer wall of the container. The interaction of construction, high-quality materials and static design ensures a long service life and high stability of the Weatherproof Silo Covers.

Product variants

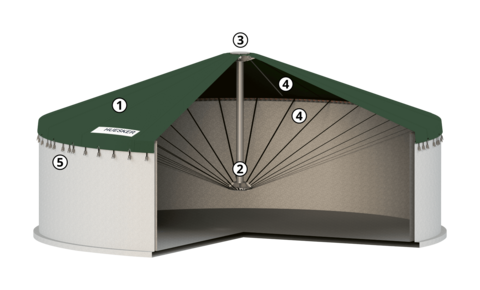

Weatherproof Silo Cover with Central Column

The Cogatec Weatherproof Silo Cover covers your tank in an emission-reducing manner and in this way ensures a permanent reduction in emissions and gases produced by agriculture. The stainless steel central column used as standard also makes it possible to cover large containers with a diameter of up to 50 m. Our roof system is carefully dimensioned according to the respective location and adapted to the specific conditions.

Construction

| (1) Weatherproof membrane (2) Central column with crown | (3) Belt construction (4) Tensioning with ratchets |

Self-supporting Weatherproof Silo Cover

The Cogatec self-supporting Weatherproof Silo Cover convinces with its low dead weight. In this way, the slurry tank is subjected to fewer loads and installation can be carried out easily. In addition, the self-supporting construction eliminates the need for complete emptying and cleaning prior to installation. This is corrosion-resistant due to the stainless steel support used and the high-tensile straps. The roof is tensioned using our specially developed stainless steel ratchets by means of a round tube inserted into the hollow seam.

Construction

| (1) Weatherproof membrane (2) Self-supporting centre | (3) Centre support crown (4) Belt construction | (5) Tensioning with ratchets (6) Abrasion protection |

Technical information

PVC-coated fabric, lacquered outside to reduce susceptibility to dirt

Tensioning with stainless steel ratchets and high-strength tensioning straps

Tear-resistant and UV-stable fabric

Stainless steel central column as standard

Static design according to local snow and wind loads

References

Do you have any questions?

Are you looking for quick answers to the most important questions about our emission control roofs, projects or subsidies? Find out now in our FAQ section! If you still can't find the answer you're looking for, simply contact us via our contact form!

In various federal states, products to reduce CO² emissions are promoted. These include, for example, Weatherproof Silo Covers for covering slurry tanks. We will be happy to advise you on the current subsidies. Just give us a call or use the contact form.

We use fabrics with fabric types II, III, IV, V. They are offered in the colour variants moss green and light grey.

The costs for a tank cover depend on the size, the design or even the conditions on site. Please fill out the contact form and we will coordinate an appointment with you to discuss all details and submit a non-binding offer.

For steel components, we use application-specific stainless steel (V2A and V4A). The alloy makes the stainless steel more resistant to corrosion.

Depending on the condition of the centre column, reuse is possible. The HUESKER centre column head can be adapted to all commercially available columns so that the existing column can continue to be used.

The installation of our roof systems depends on various factors such as the diameter or the weather. As a general rule, you can expect an installation time of about 2-5 days for an Weatherproof Silo Cover.