Our product solutions at a glance

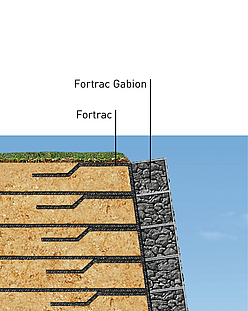

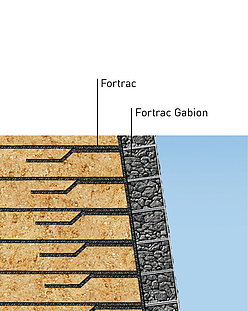

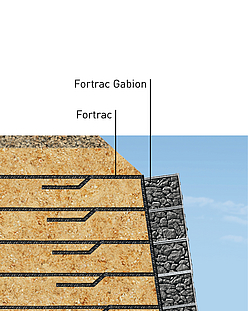

Special construction works are sometimes needed in densely populated areas to reduce the noise disturbance for local residents. GRS retaining walls, with full or partial gabion facings, for the stabilisation of embankments can be specially designed with sound absorption properties that allow them to double up as noise barriers. In Germany, the regulations and requirements governing noise control structures alongside traffic routes vary between the different federal states. Having tested various systems, HUESKER has developed a number of high-performance solutions allowing a sound absorption of up to DLa > 8-11dB.

- Up to 11 dB sound absorption

- Straightforward construction

- Harmonious integration in natural setting

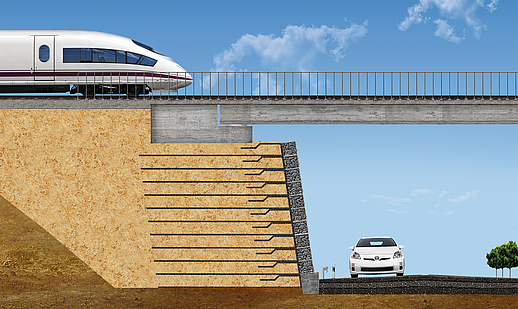

Reinforced-soil bridge abutments can be designed for direct load bearing or as part of a composite supported solution with loads partly transmitted by concrete elements, possibly in conjunction with deep pile foundations. Clients can also choose between passive and active systems, depending on whether the abutment facing is to be constructed as a load-transmitting element. GRS systems are extremely flexible and are now part of standard practice in many countries.

- Fast, efficient construction

- High ductility

- Eco-friendly

- Attractive facing design

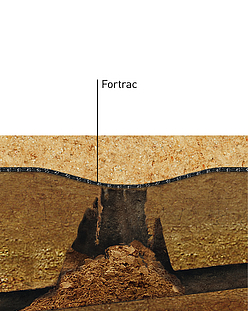

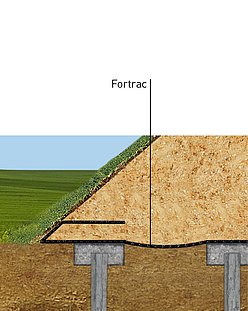

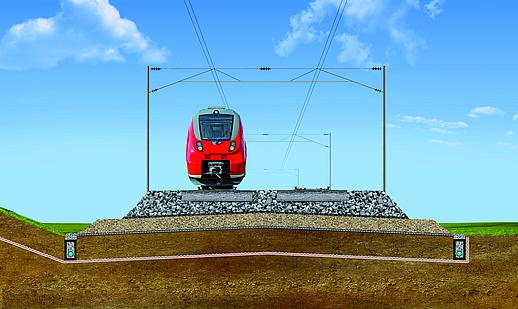

Sinkholes pose an extreme risk for rail traffic. Boasting tensile strengths of up to 3,000 kN/m coupled with high tensile stiffness, our Fortrac geogrids offer both temporary and permanent protection in areas prone to sinkholes. Not only do they eliminate the need for costly, ecologically unsustainable and less ductile reinforced-concrete structures, they are also able to cater for project-specific requirements through selection of the most suitable raw material, e.g. polyester, PVA or aramid, for the geogrid. Moreover, their inherent spare capacity can be mobilised for the short-term to accommodate sudden loads imposed by Stabilenka, Robutec unforeseen, large-diameter sinkholes.

- Structural stability in areas prone to sinkholes

- Cheaper and more eco-friendly than reinforced concrete

- Cost-effective product selection

- Inherent spare capacity to accommodate unexpected loads from large sinkholes

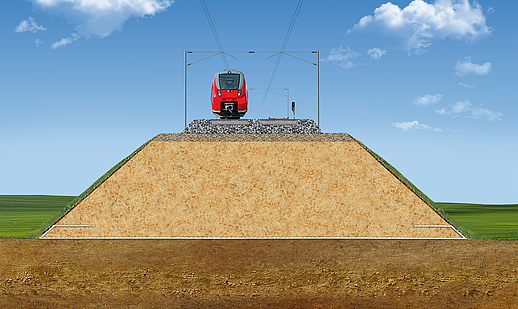

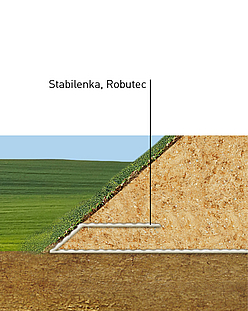

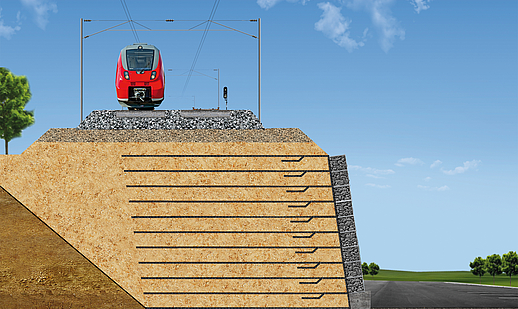

To ensure reliable, cost-efficient rail operations, railway embankments are required to offer particularly high structural stability, with a minimum of permissible deformation. With tensile strengths of up to 2,800 kN/m, reinforcement fabrics such as Stabilenka and Robutec help to speed up progress on site while reliably protecting against slope or soil shear failure. Where, for example, the use of binder modified fill materials produces an alkaline environment, then HUESKER’s Robutec polyvinyl alcohol (PVA) wovens are the products of choice.

- Rapid subsoil consolidation

- High structural stability

- Savings on fill material

- Accommodation of differential settlement

- Stabilenka

- Robutec

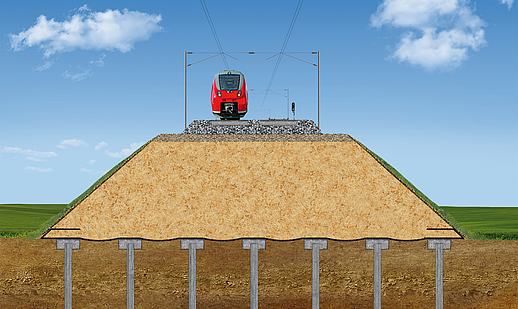

- Brochure Railway

The design of reliable embankment foundations on weak soils poses a major challenge. In addition to large-scale settlement and lateral deformation, potential risks include bearing and slope failure, or even the squeezing out of soft soil from beneath the embankment base. Where piling is installed, Fortrac geogrids allow the formation of a stable soil arch above the piles to ensure the low-settlement transmission of loads to the deeper foundation. No raked piles are required at the perimeter. At the same time, the broad selection of high-modulus, low-creep Fortrac geogrid types allows optimisation of the overall cost.

- High structural stability

- Utilisation of arching action for load transmission

- High efficiency due to large pile grid

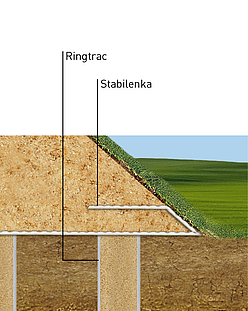

As one of the safest foundation systems for very weak subsoils, geotextile-encased columns are ideally suited to railway engineering applications. The system, which has already been used in soft strata with cu < 15 kN/m², offers high ductility and adaptability to variable subsoil conditions. Given that the dewatering effect of the Ringtrac columns, as “mega-drains”, vastly speeds up consolidation times, over 90 % of settlement takes place during the construction period. Furthermore, creep settlement is reduced by 50-75 % compared to unimproved ground. Locally sourced mineral mixes can be used as the fill material.

- Extremely reliable due to high ductility

- Rapid consolidation speeds up construction

- Cost-efficient thanks to use of locally sourced mineral mixes (sands)

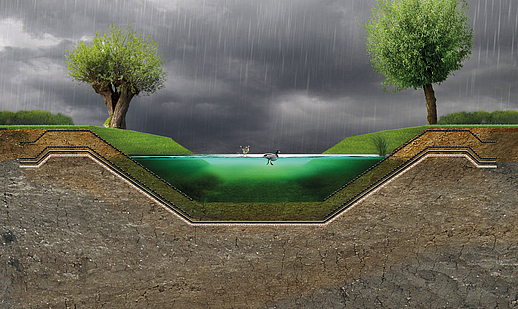

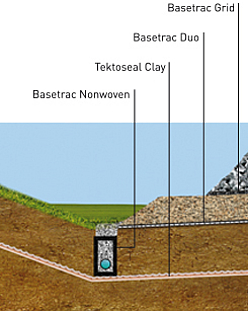

Stormwater holding basins are designed to allow the controlled discharge of large quantities of temporarily stored water. Given that the surface water may be polluted, the key component of such structures is a reliable lining system. HUESKER offers a comprehensive range of geosynthetic clay liners that are specifically designed for this function.

- Controlled discharge of large quantities of water

- Reliable lining

- Cost-effective product selection

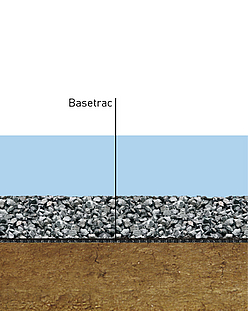

Growing traffic loads, poor drainage and deteriorating track ballast stability all contribute to the need for the rehabilitation of existing railway lines. The aim of these improvement schemes is to enhance the serviceability and extend the lifespan of linear infrastructure assets. The track bed must be able to accommodate and transmit high dynamic loads over a long service period with minimal deformation and wear. The base course construction is dictated, among other things, by the subgrade bearing capacity, the projected load levels and any applicable groundwater protection requirements. Here, HUESKER offers a wide variety of potential solutions based on its Basetrac product portfolio.

- Extension of service life

- Cost savings due to lower base course thickness

- Easy installation without memory effect

- HPQ-certified products

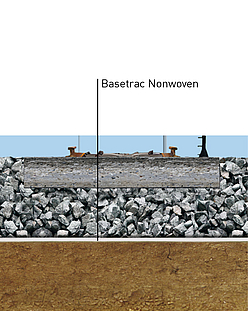

As an alternative to full-scale track subgrade improvement, specific factors and limited service periods may allow the incorporation of nonwovens directly below the track bed. The installation of highly robust nonwovens with a separation and filtration function immediately below the ballast improves surface water drainage and prevents the migration of fine particles into the crushed stone, thereby improving the bearing capacity of the base course. Our Basetrac product portfolio offers certified nonwovens for these applications.

- Improved bearing capacity

- Easy installation thanks to suitable roll widths

- HPQ-certified products

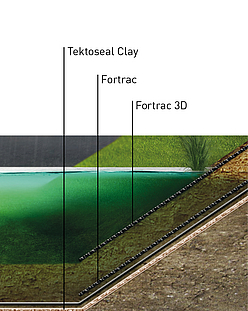

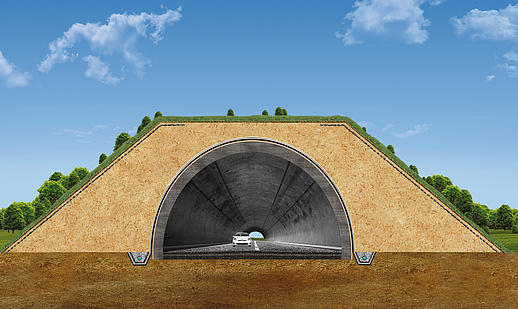

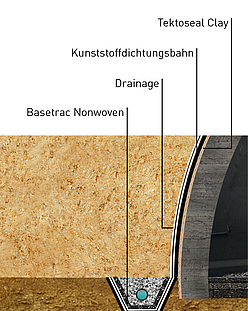

Alongside bridges, tunnels rank among the most complex structures needed for railways. A major challenge on these projects is to ensure reliable waterproofing of the tunnel cross-section. HUESKER’s answer is the specifically-developed “infiltration-proof double membrane”, which rules out any risk of leakages and the free spread of water within the waterstop compartments. Our Tektoseal Clay geosynthetic clay liners ensure enhanced reliability and durability.

- Patented system solution

- No water seepage behind membrane

- Extended service life of structure

Noise bunds, bridge abutments and steep slopes – often demanding to design and build – are a typical feature rail projects. Here, HUESKER’s geosynthetic-reinforced soil systems offer innovative and cost-effective solutions. Key advantages of GRS structures over conventional methods include their wide ranging design options, high stability and rapid onsite installation. The settlement-resistant GRS systems allow simple and efficient assembly, even for extra steep slopes.

- Customised design options

- Rapid, cost-effective installation

- Technical consulting by HUESKER engineers

- Space-efficient due to small base area

- Wide ranging applications

Both new rail projects and maintenance works generally require the construction of haul roads and other temporary access routes. These are normally subject to short, but intensive use. Particularly on sites with weak subsoils, geosynthetic solutions are often the simplest means of minimising investment and maintenance effort. Our Basetrac portfolio offers suitable products for any application – from simple separating and filtration elements to double-layer reinforcement to accommodate high loads on soft soils.

- Reliable increase in bearing capacity

- Savings on base course material

- Lower maintenance costs

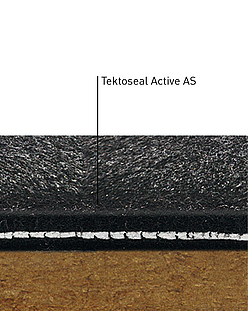

Shunting tracks, engine sheds, maintenance depots and other unpaved storage areas are susceptible to ground contamination from oil, grease and similar petrochemical products. At the same time, simple measures can be taken to eliminate the risk of soil and groundwater pollution. Tektoseal Active AS is an active geocomposite that binds harmful pollutants and prevents their infiltration into the groundwater. Key merits include the product’s high robustness and delivery in rolls to simplify installation.

- Reliable oil absorption, even over wide areas

- High mechanical strength

- Easy to install and remove

- Tektoseal Active AS

- Brochure Railway