Impoundment Lining with high-performance GCL

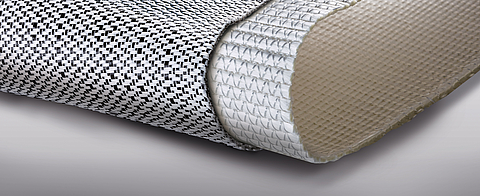

Newly built CCR impoundments require a composite liner system with a geosynthetic clay liner (GCL) and a geomembrane. However, traditional bentonite GCLs may not meet hydraulic conductivity requirements due to high ionic strength and electrical conductivity of CCR leachates. As a result of our experience in the manufacturing of GCLs, HUESKER successfully developed a unique, high performing geosynthetic clay liner. Tektoseal Clay RM solves the challenges faced with sealing CCR impoundments using a high-performance bentonite without the need for polymer blending. The unique properties of the bentonite contribute to its strong sealing capability even when permeated with aggressive leachates. This eliminates concerns with regards to service life caused by polymer loss through washout and polymer degradation over time. The easy installation of Tektoseal Clay RM ensures the long-term barrier performance required for all CCR containment applications.

Specific Benefits for CCR applications

- Unique bentonite with optimum performance in the rheological properties (swelling, thickening, cation exchange etc.)

- Very low permeability: 1.2E-09 cm/s with EPRI High Strength CCR-Leachate

- No polymer required, thus no concern for polymer loss or degradation

- The bentonite weight (load) per unit area can be adapted to project-specific needs