Incomat® Concrete Mattress

The geosynthetic concrete mattress system for hydraulic engineering

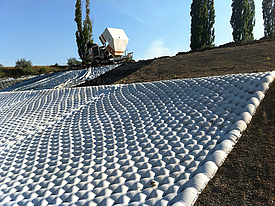

For decades, Incomat has been recognized for providing reliable erosion protection and effective surface sealing within the hydraulic engineering sector. The innovative system combines the flexibility of geotextiles with the durability of concrete—a perfect symbiosis of technology and functionality.

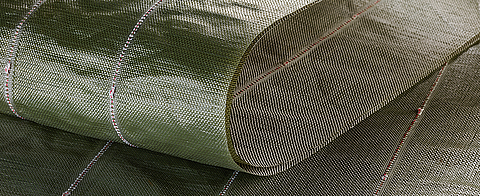

The geosynthetic concrete mattress is made of two high-strength fabric layers that are filled with fluid concrete on site. This process creates a stable, adaptable protective layer that conforms seamlessly to complex terrain—both above and below water.

Thanks to continuous development, Incomat now offers tailored solutions for embankments, riverbeds, canals, coastal zones, berth protection, and many other demanding applications. The optimized material structure of our concrete mattresses significantly reduces surface shrinkage and lowers the material required to cover surfaces by up to 35% compared to conventional solutions—delivering an environmentally friendly, cost-effective, and technically proven approach.

Discover the strength of the Incomat product family—versatile, field-tested, and ready to meet your hydraulic engineering challenges.

Lower CO2 emissions

than with conventional construction methods

Coherent system

for maximum efficiency

No formwork work required

Underwater installation

of concrete

Incomat - A strong product family

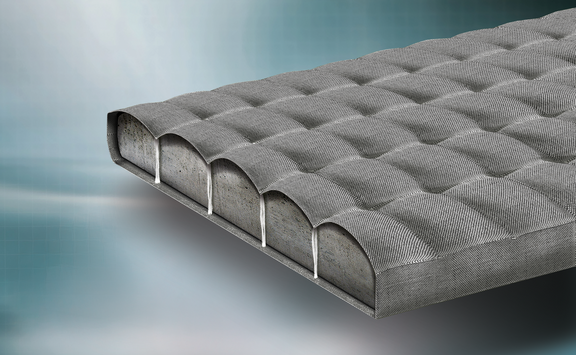

Incomat Standard

The superior product for concrete surface sealing and erosion protection

Wherever a constant concrete cross-section or an impermeable concrete mattress is required for erosion protection or sealing, Incomat Standard is the first choice. Its unique production method, featuring vertically arranged ties, delivers a level of dimensional stability in the geotextile cover unmatched anywhere in the world. This stability ensures a consistent concrete cross-section—even under challenging installation conditions, on uneven terrain, or in underwater applications. The mattress’s adaptive behavior makes it a superior solution compared to conventional concrete construction methods. In addition, the customizable design allows for easy adaptation around penetrations and complex geometries.

Incomat Standard enables the installation of a concrete seal both underwater and on steep slopes. Its integrated erosion protection function makes it the ideal solution for canal rehabilitation and basin lining projects, eliminating the need for additional protective layers or multi-layer system structures. The concrete mattress is also highly effective for providing bed protection in harbors.

Advantages and features

- Vertically arranged web ties for the greatest possible filling heights

- Constant thickness even on uneven ground

- Low hydraulic roughness compared to other concrete mattress systems

- Minimal filling shrinkage ensures adaptability to complex geometries

- Excellent system application allows for use as sole lining

Incomat Pro

Premium product for waterproofing and erosion control solutions

With Incomat Pro, unique filling heights of up to 11.5 feet can be achieved. Thanks to innovative textile technology, performance improvements of up to 95% have been realized. This translates into faster on-site construction progress and reduced installation costs. The increased tensile strength supports a more efficient filling process, ensuring greater flexibility in the field.

The optimized web ties provide maximum dimensional stability and uniform concrete distribution—even on uneven terrain or underwater installations. At the same time, reduced surface shrinkage allows for optimized material usage, conserving resources while significantly increasing project cost-effectiveness.

With these advantages, Incomat Pro is the ideal solution for demanding applications such as slope protection, canal lining, harbor bed protection, and rainwater retention and storage basins.

Advantages and features

- Increased tensile strength of up to 50 kN/m ensures safe filling

- Improved webbing design enables filling heights of up to 11.5 feet

- Increases the efficiency of the construction project and reduces costs

- Low surface shrinkage ensures material savings of up to 35%

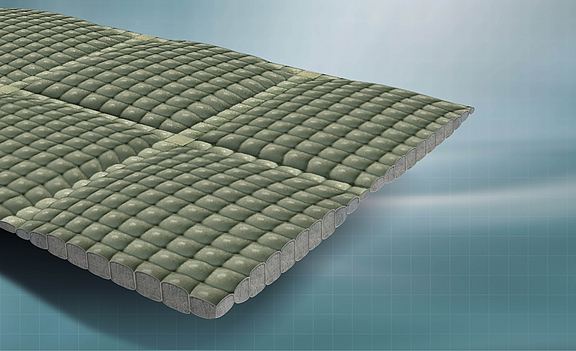

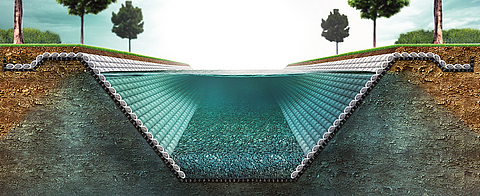

Incomat Flex

The permeable cushion mattress for high hydraulic loads

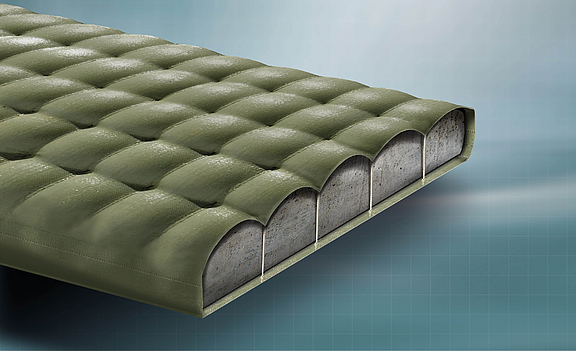

Incomat Flex is designed for applications where hydraulic loads demand a permeable mattress with higher surface weight. The production method is also based on the unique vertical spacer principle. This means that it can be produced in thicknesses of up to 24 inches.

Incomat Flex consists of individual units ("cushions") connected by joining strips. The taper in the web area acts as a predetermined breaking line, while woven-in filter points at the cushion corners help relieve hydrostatic pressure beneath the revetment. The tapered connecting strips give the mattress a certain two-dimensional flexibility in the event of subsidence in the subsoil or if the mattress is washed out.

Advantages and features

- Erosion protection under heavy hydraulic loads

- High adaptability in the event of subsidence

- Vertical tie arrangement maximizes filling height

- Continuous thickness even on uneven surfaces

- Reduction of excess pore water underneath the concrete mattress

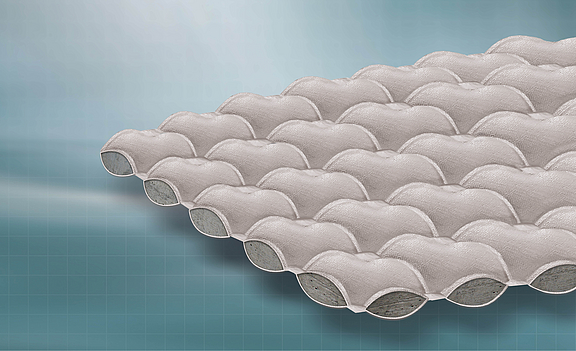

Incomat Filter Point

The permeable concrete mattress with filter points

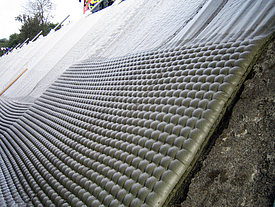

The Incomat Filter Point concrete mattress is the ideal solution for erosion control in applications with lower hydraulic loads requiring a water-permeable concrete mattress. The mattress consists of a two-layer woven fabric, and the bond between the two layers is achieved by a regular arrangement of woven filter points. By filling the mattress with concrete in situ, it conforms to the surface and reduces the likelihood of cavities forming beneath the revetment.

The Incomat Filter Point concrete mattress is generally specified as an alternative to riprap, stone revetments, or conventional concrete slabs due to its lower cost and superior performance. Incomat Filter Point provides a highly efficient and durable permeable revetment in combination with concrete, which can be used on load-bearing surfaces with low hydraulic loads.

Advantages and features

- Regular distribution of filter points across the surface

- Erosion protection for standing water or above the permanent water level

- Reduction of excess pore water pressure beneath the concrete mattress

- More economical than riprap, pitched stone or concrete slabs

- Suitable as a protective layer and ballast for plastic geomembranes

- Different concrete thicknesses possible by modifying the filter point pattern

Incomat Crib

The green concrete mattress for erosion protection

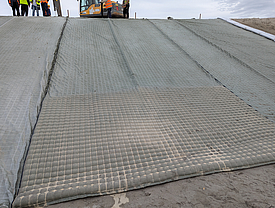

Incomat Crib consists of a tubular grid that is filled with concrete. The rectangular recesses remain unfilled and, after concreting, function as large-area filter points. Alternatively, the recessed areas can be filled with soil and subsequently vegetated.

The main areas of application for this tubular-profiled mattress are protecting overflowing dam sections and lining spillways. Once planted, Incomat Crib provides an attractive and ecological solution for erosion control.

Advantages and features

- Erosion protection for standing water or above the permanent water level

- Environmentally compatible erosion control

- Large planting areas and filter points

- Scientifically proven performance in overflow sections

- Excellent landscape integration through vegetation option

- No risk of individual stone failure compared to armor stone fills

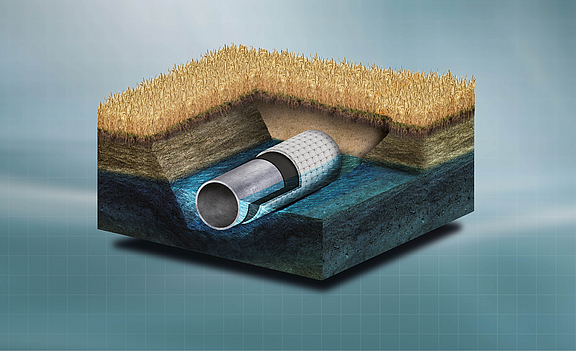

Incomat Pipeline Cover

Pipeline protection system for buoyancy and protection against external influences

Incomat Pipeline Cover (IPC) can be used wherever the protection of a pipeline against mechanical impacts or buoyancy protection is required. Unlike conventional concrete casing produced with formwork technology, the IPC system offers a quick and efficient solution.

Factory-prefabricated geotextile formwork eliminates the need for time-consuming on-site formwork. In addition, the rapid assembly of custom-made elements and the optimized concreting process enable faster construction progress. With proper planning and assembly, pipe curvatures and varying pipe diameters can be easily encased

Advantages and features

- Mechanical and buoyancy protection

- No concrete formwork required on site

- Precisely fitted factory prefabrication

- Straightforward installation for bends

- Concreting sections up to 16.4 m long

- Filling of an IPC in under 10 minutes

- Certification: No impairment of the cathodic corrosion protection

Incomat now also available as bioLine!

Sustainable erosion and pipeline protection

Incomat bio is the concrete mattress made from 100% natural raw materials, developed for ecologically sensitive construction projects in water and pipeline construction. The prefabricated panels eliminate the need for time-consuming formwork and rapid filling ensures fast construction progress—without compromising quality and sustainability.

VideoCast | Geosynthetic concrete mattress

Innovative surface sealing and erosion protection

Simple installation principle

Preparation of the formation

Spreading the panels

Filling the panels with fluid concrete/mortar

Jack Christmas

Your contact person

As Hydraulic Product Manager for HUESKER North America, Jack Christmas leads in the execution of design, product development, and sales strategies throughout various waterborne applications. He has extensive experience in designing solutions utilizing geosynthetics for Berth & Scour, Sludge Dewatering, Coastal Protection, and Buoyancy and Uplift Protection in Pipelines. Jack received a B.S. in Civil Engineering from Louisiana State University and currently has extensive experience providing product recommendations throughout North America.